Biodegradable Revolution in Orthopedic 3D Printing: Atomized Spherical Magnesium Alloy Powder for Bone Repair Implants

Introduction

As global populations age, the demand for orthopedic implants continues to rise. According to MarketsandMarkets 2024, the biodegradable implants market is projected to reach nearly USD 10 billion by 2030. Among emerging biomaterials, magnesium alloys have drawn significant attention due to their excellent biocompatibility and natural biodegradability, making them ideal for next-generation bone repair applications.

Technical Challenges

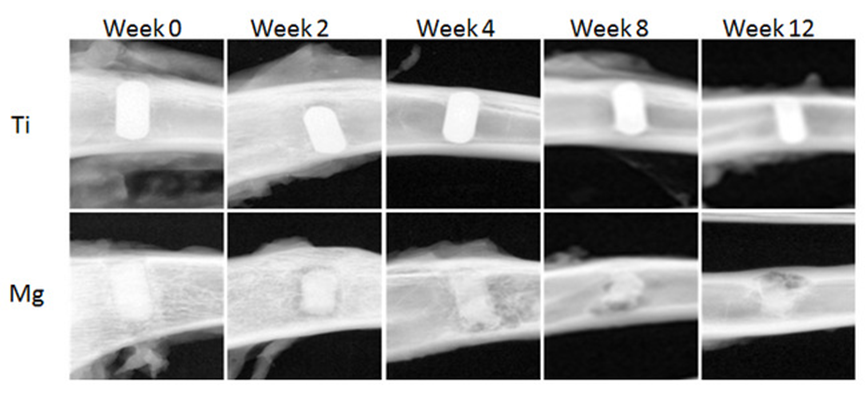

Conventional implant materials such as titanium and stainless steel are mechanically strong but require secondary removal surgeries—increasing patient trauma and healthcare costs.

Magnesium alloys can naturally degrade in the human body, but their manufacturing process presents challenges:

- High oxidation tendency and gas porosity;

- Irregular particle morphology, reducing 3D printing stability;

- Insufficient part density, limiting strength and corrosion resistance.

The Weihao Solution

At Tangshan Weihao Magnesium Powder Co., Ltd., we deliver high-purity atomized spherical magnesium alloy powder specifically optimized for medical 3D printing:

- High Purity (≥99.95%) – Minimizes impurities and reduces inflammation risk.

- Superior Sphericity & Flowability – Ensures smooth powder spreading, consistent layer deposition, and excellent surface finish.

- High Packing Density – Reduces interlayer gaps, forming dense melt pools during laser fusion and achieving mechanical strength close to wrought materials.

Visit www.tswhmf.com to learn more about our advanced medical-grade magnesium powder.

Applications

Our powders are ideal for:

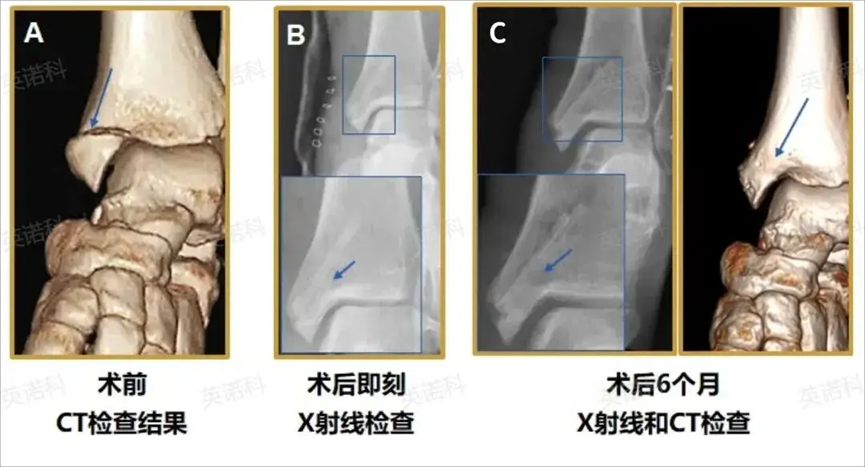

- 3D printed biodegradable orthopedic implants

- Bone screws, fixation plates, and maxillofacial scaffolds

- Personalized bone repair solutions combining strength, bioactivity, and full degradability

About Tangshan Weihao Magnesium Powder

Founded in 2000, Tangshan Weihao Magnesium Powder Co., Ltd. specializes in atomized spherical magnesium and magnesium alloy powders, serving industries including aerospace, automotive, biomedical, and consumer electronics. With patented multi-stage atomization technology and over two decades of R&D experience, Weihao leads the shift toward lightweight, energy-efficient, and precision manufacturing solutions.

Partner With Us

If your organization is pursuing innovation in lightweight and biodegradable implant materials, we welcome collaboration:

- 🔬 Custom Powder Development – Tailored magnesium and alloy powders for medical 3D printing

- 🤝 Joint Research Opportunities – Co-develop next-generation biodegradable metal implants

Tangshan Weihao Magnesium Powder Co., Ltd.

🌐 Website: www.tswhmf.com

📧 Email: info@tswhmf.com

📞 Tel: +86-315-2510616

FAQ

Q1: Why is magnesium alloy suitable for orthopedic implants?

A1: Magnesium alloy has an elastic modulus similar to bone tissue and excellent biocompatibility. It can gradually degrade in vivo, avoiding secondary surgical removal.

Q2: How can Tangshan Weihao's magnesium powder improve the quality of 3D printing molding?

A2: High sphericity and low oxygen content ensure good flowability and melting uniformity of the powder, resulting in high density and stable strength of the formed parts.

Q3: Can different magnesium alloy compositions be customized?

A3: Sure. Weihao can customize alloy systems, particle size distribution, and surface treatment solutions according to customer project requirements.

Comments

Post a Comment